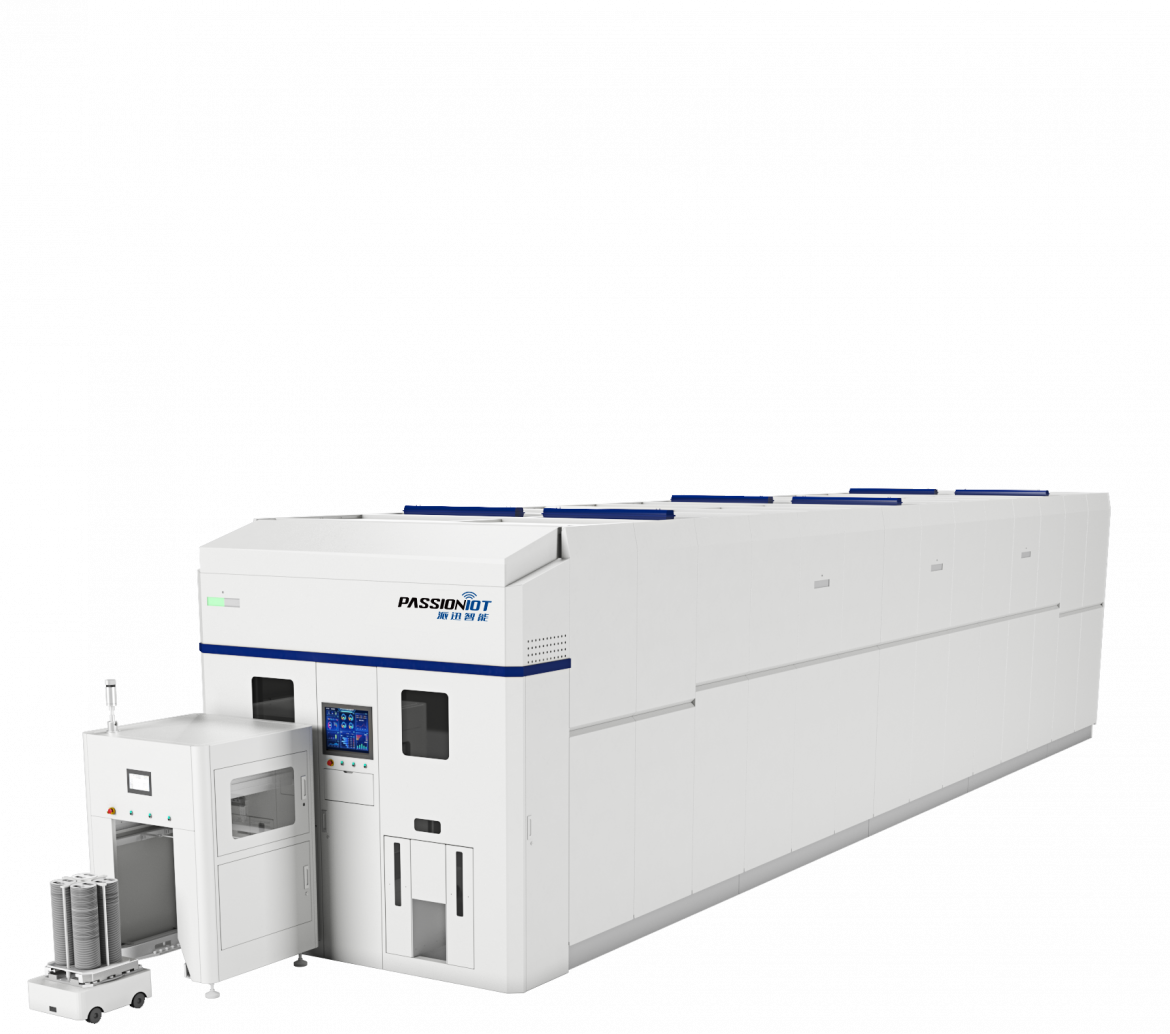

As the global manufacturing landscape continues to evolve, many businesses are exploring how automation can improve their warehouse operations. The integration of advanced warehouse automation solutions and SMD storage systems is playing a crucial role in transforming traditional warehouses into more efficient, agile, and productive environments. PassionIOT is at the forefront of this change, offering high-tech solutions that help manufacturers streamline their material handling processes. In this article, we will explore how PassionIOT’s automation solutions are shaping the future of warehousing.

The Role of Warehouse Automation in Modern Manufacturing

In today’s fast-paced manufacturing environments, companies are constantly seeking ways to optimize their workflows. Implementing warehouse automation solutions can significantly enhance material handling, reduce human error, and improve overall productivity. By integrating cutting-edge automation technologies, warehouses can not only keep up with growing demand but also adapt to new operational challenges. With PassionIOT’s advanced solutions, companies are able to achieve seamless material distribution and improved line-side storage.

The integration of SMD storage systems is especially valuable in industries where the demand for precision and speed is high. These systems ensure that materials are organized efficiently and are easily accessible, reducing downtime and enabling faster decision-making. By automating key processes, companies can reduce the strain on their workforce while improving operational efficiency.

Key Features of PassionIOT’s Warehouse Automation Solutions

One of the standout features of PassionIOT’s warehouse automation solutions is their seamless integration with SMD storage systems, which are critical for managing delicate or small components. PassionIOT designs its solutions with the latest technologies to ensure a smooth operation in complex environments. These systems are highly adaptable, enabling businesses to easily scale their automation as their needs grow.

Additionally, PassionIOT offers advanced tracking and monitoring capabilities, ensuring that manufacturers can maintain full visibility over their material flow. This level of automation and control leads to significant improvements in both production speed and accuracy. The warehouse automation solutions from PassionIOT also reduce the risk of errors in material handling, ensuring a more consistent output.

Real-World Impact: Case Studies from Major Manufacturers

Several major manufacturers have already embraced PassionIOT’s warehouse automation solutions to boost their operational efficiency. For instance, Foxconn, a global player in electronics manufacturing, utilizes PassionIOT’s solutions to streamline material handling in their vast production lines. By implementing SMD storage systems and automation technologies, Foxconn has been able to significantly reduce operational delays and increase their throughput.

Similarly, companies like Midea and Xiaomi have successfully incorporated PassionIOT’s warehouse automation solutions to support their growing manufacturing needs. These businesses have seen marked improvements in both the speed of production and the accuracy of inventory management, thanks to the integration of SMD storage systems and automated material handling systems. PassionIOT has helped them achieve better synchronization between different production stages, leading to a smoother, more efficient workflow.

Conclusion

Incorporating PassionIOT’s warehouse automation solutions and SMD storage systems into your warehouse operations can significantly improve efficiency and reduce operational costs. By automating key processes, manufacturers can enhance their material management, improve storage systems, and optimize production workflows. For businesses looking to stay competitive in the ever-evolving manufacturing landscape, investing in advanced warehouse automation is a critical step.